Grafit elektrodlari Nipellar 3tpi 4tpi ulash pin T3l T4l

Tavsif

Grafit elektrodli nipel EAF po'lat ishlab chiqarish jarayonining kichik, ammo muhim qismidir. Bu elektrodni o'choqqa bog'laydigan silindrsimon shakldagi komponent. Po'lat ishlab chiqarish jarayonida elektrod o'choqqa tushiriladi va eritilgan metall bilan aloqa qiladi. Elektr toki elektrod orqali o'tadi, issiqlik hosil qiladi, bu esa o'choqdagi metallni eritadi. Nipel elektrod va pech o'rtasidagi barqaror elektr aloqasini ta'minlashda hal qiluvchi rol o'ynaydi.

Texnik parametr

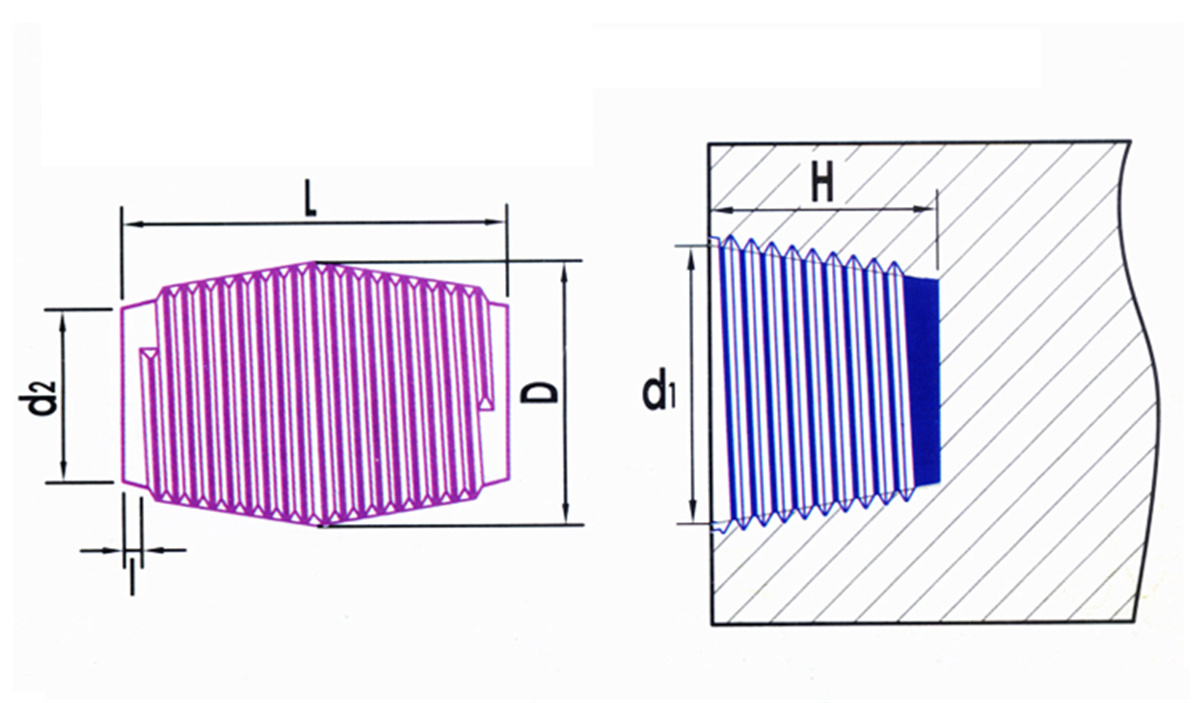

Gufan karbonli konusli nipel va rozetka chizish

| Nominal diametri | IEC kodi | Nipel o'lchamlari (mm) | Soket o'lchamlari (mm) | Pitch | |||||

| mm | dyuym | D | L | d2 | I | d1 | H | mm | |

| Tolerantlik (-0,5~0) | Tolerantlik (-1~0) | Tolerantlik (-5~0) | Tolerantlik (0~0,5) | Tolerantlik (0~7) | |||||

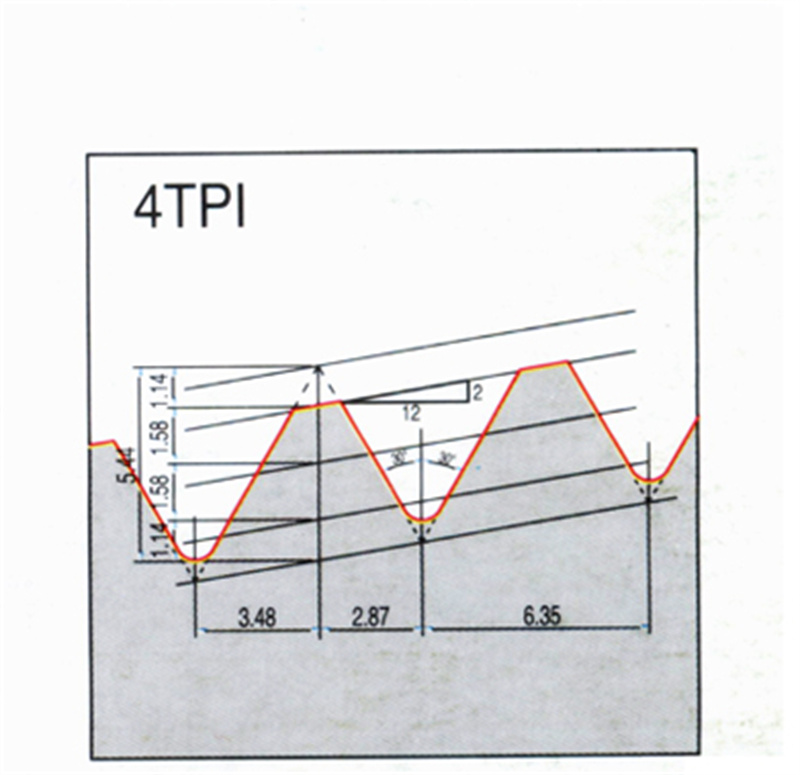

| 200 | 8 | 122T4N | 122.24 | 177,80 | 80.00 | <7 | 115,92 | 94,90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190,50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177,80 | 215,90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4L | 222.25 | 355,60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 304.80 | 177,90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 355,60 | 169.42 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269,88 | 355,60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269,88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 355,60 | 226.58 | 292.13 | 183.80 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317.50 | 355,60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317.50 | 457.20 | 228,70 | 311.18 | 234.60 | ||

| 650 | 26 | 355T4N | 355,60 | 457.20 | 266,79 | 349.28 | 234.60 | ||

| 650 | 26 | 355T4L | 355,60 | 558,80 | 249,66 | 349.28 | 285.40 | ||

| 700 | 28 | 374T4N | 374,65 | 457.20 | 285,84 | 368.33 | 234.60 | ||

| 700 | 28 | 374T4L | 374,65 | 558,80 | 268,91 | 368.33 | 285.40 | ||

| Nominal diametri | IEC kodi | Nipel o'lchamlari (mm) | Soket o'lchamlari (mm) | Pitch | |||||

| mm | dyuym | D | L | d2 | I | d1 | H | mm | |

| Tolerantlik (-0,5~0) | Tolerantlik (-1~0) | Tolerantlik (-5~0) | Tolerantlik (0~0,5) | Tolerantlik (0~7) | |||||

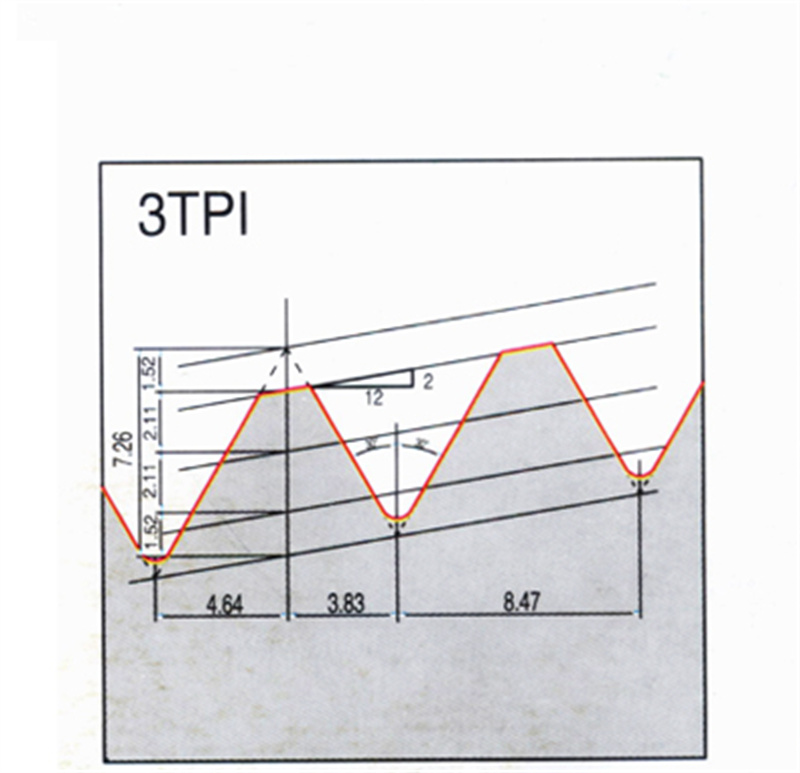

| 250 | 10 | 155T3N | 155,57 | 220.00 | 103.80 | <7 | 147.14 | 116.00 | 8.47 |

| 300 | 12 | 177T3N | 177.16 | 270,90 | 116,90 | 168,73 | 141.50 | ||

| 350 | 14 | 215T3N | 215,90 | 304.80 | 150.00 | 207.47 | 158.40 | ||

| 400 | 16 | 241T3N | 241.30 | 338,70 | 169,80 | 232.87 | 175.30 | ||

| 450 | 18 | 273T3N | 273.05 | 355,60 | 198.70 | 264.62 | 183.80 | ||

| 500 | 20 | 298T3N | 298.45 | 372,60 | 221.30 | 290.02 | 192.20 | ||

| 550 | 22 | 298T3N | 298.45 | 372,60 | 221.30 | 290.02 | 192.20 | ||

| Elektrod | Nipellarning standart og'irligi | ||||||||

| Nominal elektrod hajmi | 3TPI | 4TPI | |||||||

| Diametri × Uzunlik | T3N | T3L | T4N | T4L | |||||

| dyuym | mm | funt | kg | funt | kg | funt | kg | funt | kg |

| 14 × 72 | 350 × 1800 | 32 | 14.5 | - | - | 24.3 | 11 | - | - |

| 16 × 72 | 400 × 1800 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 16 × 96 | 400 × 2400 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 18 × 72 | 450 × 1800 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 18 × 96 | 450 × 2400 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 20 × 72 | 500 × 1800 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 84 | 500 × 2100 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 96 | 500 × 2400 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 110 | 500 × 2700 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 22 × 84 | 550 × 2100 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 22 × 96 | 550 × 2400 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 24 × 84 | 600 × 2100 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 96 | 600 × 2400 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 110 | 600 × 2700 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| Elektrod diametri | dyuym | 8 | 9 | 10 | 12 | 14 |

| mm | 200 | 225 | 250 | 300 | 350 | |

| Yengillash momenti | N·m | 200–260 | 300–340 | 400–450 | 550–650 | 800–950 |

| Elektrod diametri | dyuym | 16 | 18 | 20 | 22 | 24 |

| mm | 400 | 450 | 500 | 550 | 600 | |

| Yengillash momenti | N·m | 900–1100 | 1100–1400 | 1500–2000 | 1900–2500 | 2400–3000 |

O'rnatish bo'yicha ko'rsatma

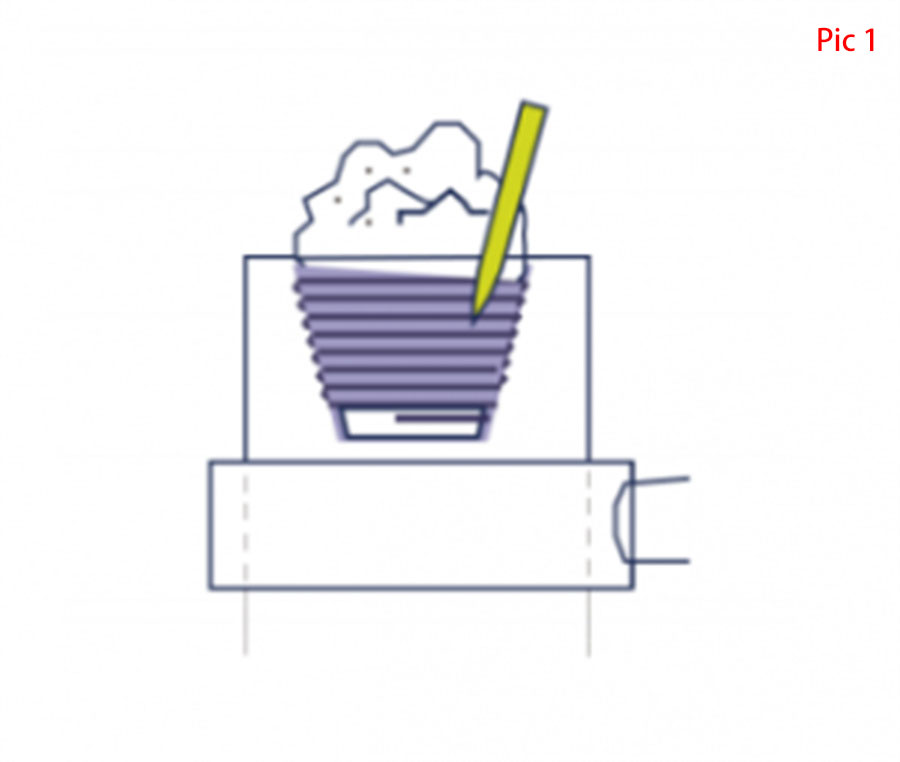

- Grafit elektrod nipelini o'rnatishdan oldin, elektrod va nipel yuzasidagi chang va kirni siqilgan havo bilan tozalang; (1-rasmga qarang)

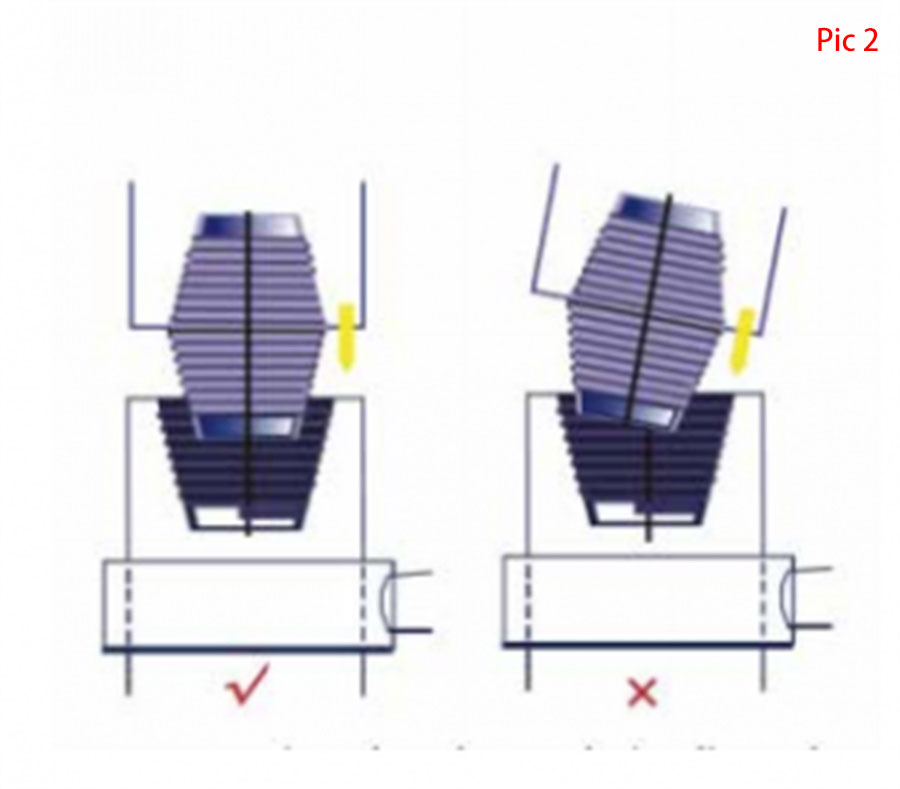

- Grafit elektrod nipelining o'rta chizig'i ikkita bo'lak grafit elektrodlarini bir-biriga ulashda izchil bo'lishi kerak; (2-rasmga qarang)

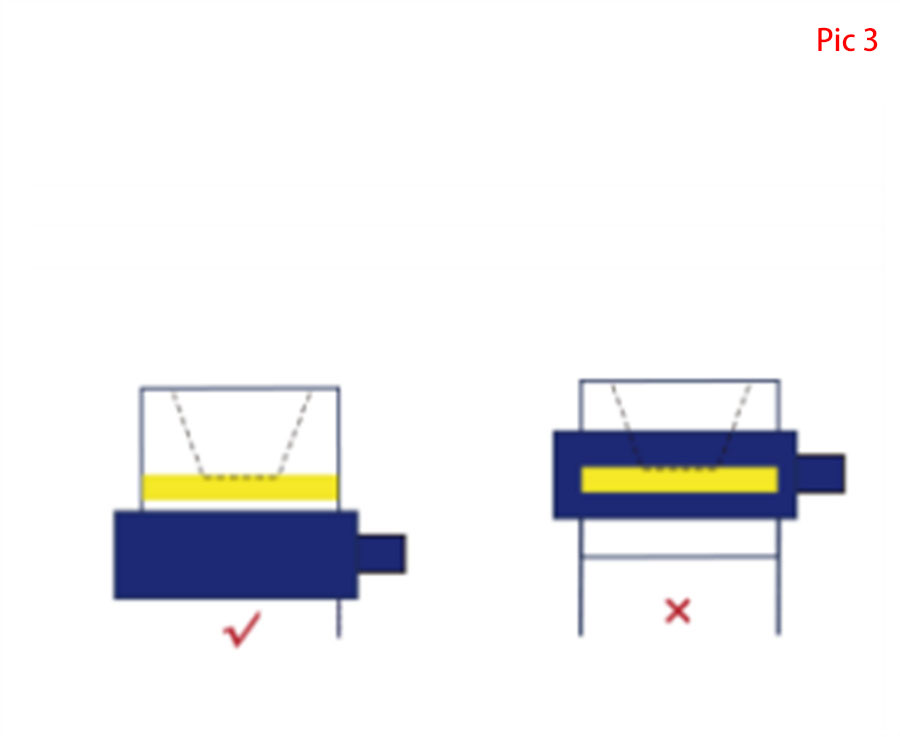

- Elektrod qisqichi to'g'ri holatda ushlab turilishi kerak: yuqori uchining xavfsizlik liniyalaridan tashqarida; (3-rasmga qarang)

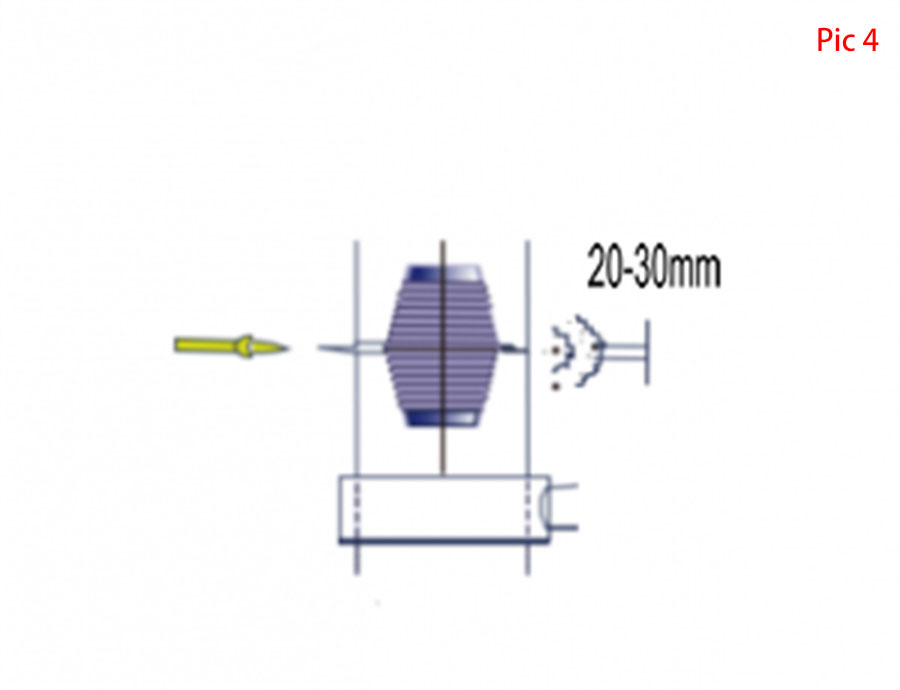

- Nipelni mahkamlashdan oldin, nipel yuzasi chang yoki iflosliksiz tozaligini ta'minlang. (4-rasmga qarang)

Grafit elektrod nipel EAF po'lat ishlab chiqarish jarayonida muhim komponent hisoblanadi. Uning sifati jarayonning samaradorligi va ishonchliligiga bevosita ta'sir qiladi. Yuqori sifatli nipellardan foydalanish elektrod avariyalarining oldini olish va silliq va samarali po'lat ishlab chiqarish jarayonini ta'minlash uchun juda muhimdir.Sanoat ma'lumotlariga ko'ra, elektrod avariyalarining 80% dan ortig'i singan nipellar va bo'shashmasdan qoqilish natijasida yuzaga keladi. To'g'ri nipelni tanlash uchun quyidagi omillarni hisobga olish kerak.

- Issiqlik o'tkazuvchanligi

- Elektr qarshiligi

- Zichlik

- Mexanik kuch

Grafit elektrod nipelini tanlashda uning sifati, o'lchami va shakli, elektrod va pechning texnik xususiyatlariga muvofiqligini hisobga olish kerak. To'g'ri nipelni tanlab, ishlab chiqaruvchilar po'lat sifatini yaxshilashlari va ishlamay qolishlari va past mahsuldorlik bilan bog'liq xarajatlarni kamaytirishlari mumkin.

Shu jumladan uning issiqlik o'tkazuvchanligi, elektr qarshiligi, zichligi va mexanik kuchi.