Yuqori zichlikdagi kichik diametrli o'choqli grafit elektrodi po'lat eritishda cho'milish pechlari uchun yuqori o'choq

Texnik parametr

1-chizma: Kichik diametrli grafit elektrod uchun texnik parametr

| Diametri | Qism | Qarshilik | Bukilish kuchi | Yosh modul | Zichlik | CTE | Ash | |

| dyuym | mm | mk·m | MPa | Gpa | g/sm3 | ×10-6/℃ | % | |

| 3 | 75 | Elektrod | 7,5-8,5 | ≥9,0 | ≤9.3 | 1,55-1,64 | ≤2.4 | ≤0,3 |

| Nipel | 5,8-6,5 | ≥16,0 | ≤13,0 | ≥1,74 | ≤2,0 | ≤0,3 | ||

| 4 | 100 | Elektrod | 7,5-8,5 | ≥9,0 | ≤9.3 | 1,55-1,64 | ≤2.4 | ≤0,3 |

| Nipel | 5,8-6,5 | ≥16,0 | ≤13,0 | ≥1,74 | ≤2,0 | ≤0,3 | ||

| 6 | 150 | Elektrod | 7,5-8,5 | ≥8,5 | ≤9.3 | 1,55-1,63 | ≤2.4 | ≤0,3 |

| Nipel | 5,8-6,5 | ≥16,0 | ≤13,0 | ≥1,74 | ≤2,0 | ≤0,3 | ||

| 8 | 200 | Elektrod | 7,5-8,5 | ≥8,5 | ≤9.3 | 1,55-1,63 | ≤2.4 | ≤0,3 |

| Nipel | 5,8-6,5 | ≥16,0 | ≤13,0 | ≥1,74 | ≤2,0 | ≤0,3 | ||

| 9 | 225 | Elektrod | 7,5-8,5 | ≥8,5 | ≤9.3 | 1,55-1,63 | ≤2.4 | ≤0,3 |

| Nipel | 5,8-6,5 | ≥16,0 | ≤13,0 | ≥1,74 | ≤2,0 | ≤0,3 | ||

| 10 | 250 | Elektrod | 7,5-8,5 | ≥8,5 | ≤9.3 | 1,55-1,63 | ≤2.4 | ≤0,3 |

| Nipel | 5,8-6,5 | ≥16,0 | ≤13,0 | ≥1,74 | ≤2,0 | ≤0,3 | ||

2-chizma: Kichik diametrli grafit elektrod uchun oqim o'tkazuvchanligi

| Diametri | Joriy yuk | Joriy zichlik | Diametri | Joriy yuk | Joriy zichlik | ||

| dyuym | mm | A | A/m2 | dyuym | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

3-chizma: Grafit elektrodining o‘lchami va kichik diametrli grafit elektrod uchun bardoshliligi

| Nominal diametri | Haqiqiy diametri (mm) | Nominal uzunlik | Tolerantlik | |||

| dyuym | mm | Maks. | Min. | mm | dyuym | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Asosiy dastur

- Kaltsiy karbidini eritish

- Karborund ishlab chiqarish

- Korundni tozalash

- Nodir metallarni eritish

- Ferrosilikon zavodi o'tga chidamli

Grafit elektrodlari uchun ko'rsatmalar berish va foydalanish

1. Grafit elektrodini tashish paytida shikastlanmaslik uchun maxsus ko'tarish asboblaridan foydalaning. (1-rasmga qarang)

2.Grafit elektrod namlanmasligi yoki yomg'ir, qor, quruq holda saqlanishi kerak (2-rasmga qarang)

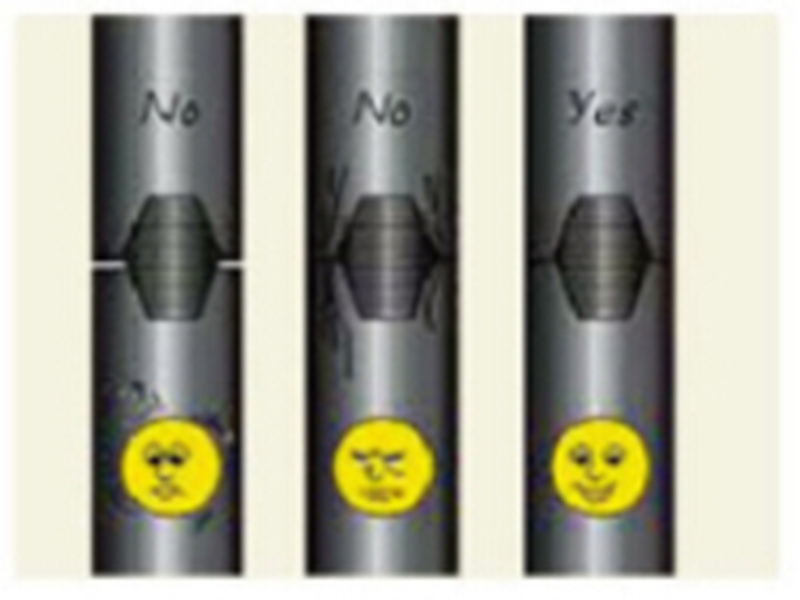

3. Ishlatishdan oldin diqqat bilan tekshirib ko'ring, rozetka va nipel ipining foydalanishga yaroqliligiga ishonch hosil qiling, shu jumladan pitch, vilkani tekshirish (3-rasmga qarang)

4. Nipel va rozetkalarning iplarini siqilgan havo bilan tozalang.(4-rasmga qarang)

5. Foydalanishdan oldin grafit elektrod o'choqda quritilishi kerak, quritish harorati 150 ℃ dan past bo'lishi kerak, quritish vaqti 30 soatdan ortiq bo'lishi kerak. (5-rasmga qarang)

6.Grafit elektrod mos keladigan tortish momenti bilan mahkam va to'g'ri ulangan bo'lishi kerak. (6-rasmga qarang)

7. Grafit elektrodining sinishi oldini olish uchun katta qismini pastki holatga va kichik qismini yuqori holatga qo'ying.